24-Hour Flash Sale – Grab Your Deal Now! • 🎊Discount up to 35% for first purchase only this month. • ⏳ Winter Sale Amazing Ramadan Deals Discounts Offers is live Now • 🚚 Free Delivery on Orders up to Rs. 2,500! • 🛍️ Limited Stock – Shop Before It’s Gone! •

24-Hour Flash Sale – Grab Your Deal Now! • 🎊Discount up to 35% for first purchase only this month. • ⏳ Winter Sale Amazing Ramadan Deals Discounts Offers is live Now • 🚚 Free Delivery on Orders up to Rs. 2,500! • 🛍️ Limited Stock – Shop Before It’s Gone! •

24-Hour Flash Sale – Grab Your Deal Now! • 🎊Discount up to 35% for first purchase only this month. • ⏳ Winter Sale Amazing Ramadan Deals Discounts Offers is live Now • 🚚 Free Delivery on Orders up to Rs. 2,500! • 🛍️ Limited Stock – Shop Before It’s Gone! •

24-Hour Flash Sale – Grab Your Deal Now! • 🎊Discount up to 35% for first purchase only this month. • ⏳ Winter Sale Amazing Ramadan Deals Discounts Offers is live Now • 🚚 Free Delivery on Orders up to Rs. 2,500! • 🛍️ Limited Stock – Shop Before It’s Gone! •

24-Hour Flash Sale – Grab Your Deal Now! • 🎊Discount up to 35% for first purchase only this month. • ⏳ Winter Sale Amazing Ramadan Deals Discounts Offers is live Now • 🚚 Free Delivery on Orders up to Rs. 2,500! • 🛍️ Limited Stock – Shop Before It’s Gone!

24-Hour Flash Sale – Grab Your Deal Now! 🎊Discount up to 35% for first purchase only this month. • ⏳ Winter Sale Amazing Ramadan Deals Discounts Offers is live Now • 🚚 Free Delivery on Orders up to Rs. 2,500! • 🛍️ Limited Stock – Shop Before It’s Gone! •

Why Butterfly Valve CI Body Is Ideal for Industries

Facebook

Twitter

Pinterest

LinkedIn

Why Butterfly Valve CI Body Is Ideal for Industries

The efficient control of flow is paramount for the productivity, safety, and cost of industrial systems. That is Why Butterfly Valve CI Body Is Ideal for Industries is one of the most trusted components of industrial pipelines. Because of its compact body and reliable performance and strength, it is used across industries in Pakistan, particularly in manufacturing, water supply, HVAC, and general utility systems.

This guide will explain why butterfly valve CI body solutions are viewed as the most suitable for industrial applications. It will explain their functionality, industrial applications, and the importance of their size in relation to overall industrial systems efficiency.

Understanding Why Butterfly Valve CI Body Is Ideal for Industries Technology

The body of one butterfly valve contains a rotating disc coupled with a circular valve. When the disc is spun parallel to the axis of the pipe, it allows free fluid flow. When it rotates in the perpendicularly, it stops the flow. Its CI body provides sufficient strength to the valve and industrial environments for medium to high pressure.

The design is simple, and assures rapid operation, low wear and reliable performance. It also allows for lesser maintenance compared to more complex valve systems. Because of its design, it is easier than more sophisticated valve systems to maintain.

Strength and Durability for Industrial Conditions

Industries value the durability of the Why Butterfly Valve CI Body Is Ideal for Industries designs. Cast iron is praised for its superior mechanical strength and its resistance to deformation. Durability is paramount in the industrial environment of pipelines which endure pressure fluctuations, and constant use with high levels of vibration.

The robust CI body safeguards the internal parts and guarantees the valve’s long service life. This is what makes it a reliable choice for the factories, plants, and infrastructure projects in Pakistan, where dependability is crucial.

Efficient Flow Control with Minimal Pressure Drop

The design of Why Butterfly Valve CI Body Is Ideal for Industries presents optimum control of flow in its most elaborate form in a way that the user is able to enjoy the most simplicity. The design of the disk is such that it makes it possible for the fluid to flow with the slightest of obstructions, and thus the least amount of pressure is lost across the valve. This results in improved efficiency of the entire system and the consumption of energy is reduced as well.

This is especially beneficial to the industries that use pumps and compressors. The amount of pressure lost is not high and therefore the equipment is not subjected to stress, and in the long run, it enhances the system’s performance and reduces the operational expenses.

Butterfly Valve CI Body Dia: 2” – Compact Solution for Controlled Flow

Precise flow control is important for smaller pipelines. The Butterfly Valve CI Body Dia: 2″ is designed for this purpose. This size is typically utilized in HVAC systems, water distribution lines, and small-scale industrial processes.

Delivering reliable sealing and smooth operation, its compact structure allows for easy installation in even the most tight and limited spaces. This size is preferred in most industries for applications that demand space efficiency, controlled flow, and smooth operation.

Butterfly Valve CI Body Dia: 3” – Balanced Power for Medium Pipelines

Among medium-sized pipeline systems, the Butterfly Valve CI Body Dia: 3” has the most balanced flow capacity control. The 3” size is most commonly designed in industrial water systems, irrigation networks and processing plants.

Maintaining the benefits of compact design, and easy operation, the 3-inch diameter improves the flow rate, making it even more efficient. This versatility makes it a frontrunner in industry selections.

Compact Design and Space-Saving Benefits

When compared to globe valves and gate valves, CI Why Butterfly Valve CI Body Is Ideal for Industries valves are more compact and lightweight. This added design benefit is most important in industrial plants with a lot of closely running multiple pipelines.

Reduced size and weight not only make handling and installation easier, but also reduce labor and installation costs. This makes butterfly valves, for many industrial upgrades and retrofitting projects in Pakistan, very practical to use.

Broad Industrial Utility

Why Butterfly Valve CI Body Is Ideal for Industries are utilized in different industries. Examples include water treatment plants, fire protection systems, HVAC systems, irrigation, and manufacturing.

They also offer industrial customers a wider selection of products, because these valves can be used with various fluids including water, air, and certain chemicals.

Optimal for Large Scale Projects

In large industrial projects, which typically include extensive networks of pipelines, cost becomes very important. Overall, Why Butterfly Valve CI Body Is Ideal for Industries are more affordable than many other alternatives and in large diameters particularly economically.

The use of cast iron keeps manufacturing costs down and, without sacrificing strength, makes the products more affordable which is important for large scale projects.

Simple Installation and Minimal Maintenance

Why Butterfly Valve CI Body Is Ideal for Industries bodies also require minimal maintenance. These valves are installed easily and are typically positioned between the flanges. This leads to a reduction in required parts and installation time. Overall, this decreases downtime in the maintenance or setup of a system.

Keeping the valves in good working condition is also simple due to their internal features. They are good to go with routine checking and minimal servicing, which is good for the hustle and bustle of the working industrial area.

Sealing and the Safety of the Operation Being Reliable

There are no exceptions to the industrial systems needing valves that are reliable in their sealing so that they do not leak and are safe to use. The bodies of the butterfly valves CI are made to give shut off which is not escape able if they are properly adjusted and performed and are within the specified limits.

This gives sealing that is dependable so there is no loss of fluid, the danger is not there, and the system is operational the way it is meant to be. Especially with companies that are safety concerned and are working with systems that are under pressure.

The Compatibility with Automated and Manual Systems

A large part of the industrial systems these days incorporate automation for more control and efficiency. The bodies of Why Butterfly Valve CI Body Is Ideal for Industries are compatible with manual systems, with automated systems, with levers, with gear operators and with electro pneumatic actuators.

This compatibility means that the industries do not have to replace the entire valve system if they want to shift from manual to automated systems. This flexibility is great for planning in the long run.

The industrial butterfly valve CI bodies of Pakistan.

The industrial conditions in Pakistan can be tough. There are variations of temperature, of dust and of operation which is continuous. Why Butterfly Valve CI Body Is Ideal for Industries bodies can be relied upon in these conditions if careful selection and maintenance is done.

Coatings and linings improve protection from corrosion and other environmental factors. This makes them appropriate for indoor and outdoor installations, even in challenging environments.

Why Trusted Suppliers Appeal to Industrial Buyers

Choosing the right supplier is as critical as choosing the appropriate valve. Industrial buyers tend to use Dayshop.pk type platforms to find dependable butterfly valve CI body options satisfying the local industry.

Having access to trustworthy products and steady specifications makes project execution uncomplicated and makes them satisfied for the foreseeable future.

Engineering Assurance and Quality Norms

Why Butterfly Valve CI Body Is Ideal for Industries bodies manufactured according to the applicable engineering standards guarantee operational and safety reliability. These standards assist industries in achieving operational and other applicable industry regulations.

Engineers and system designers prefer elements that reduce system design complexity in addition to providing reliable outcomes. These expectations are well met by the Why Butterfly Valve CI Body Is Ideal for Industries

Return on Investment and Long-Term Value

Apart from the initial savings on cost, the Why Butterfly Valve CI Body Is Ideal for Industries bodies create enduring value because they are reliable, require infrequent maintenance, and operationally efficient. Less downtime and fewer replacements are an achievable operational goal leading to improved returns on the investment.

Reliable valve solutions with proven performance are preferable to industries that want to maintain operational sustainability and control costs.

Choosing the Best Butterfly Valve CI Body In Pakistan

For businesses wanting to buy industrial valves, Dayshop.pk lists several options for Why Butterfly Valve CI Body Is Ideal for Industries bodies for varying applications and sizes.

Reliable sourcing brings genuine products, accurate specs, and an overall assurance for the valves’ performance for the years to come.

Final Thoughts

Why Butterfly Valve CI Body Is Ideal for Industries is ideal for any kind of industry, with its powerful, effective and compact design and its great price point. This valve type provides great flow control, whether for smaller systems with a Butterfly Valve CI Body Dia: 2” or for medium pipelines with a Butterfly Valve CI Body Dia: 3”.

The valve’s wide use across industries, the easy installation and the long service time makes it a great and cost effective option for multiple industrial projects in Pakistan. Dayshop.pk is one of the platforms that industrial components providers frequent to obtain the components that will facilitate successful and productive work.

Selecting the right butterfly valve CI body helps industries streamline their processes, enhance safety, and provides operational consistency and reliability for years to come.

Tags:

Product on Sale

-

Sale!

Classic Rolex Two Tone Watch For Women

₨ 3,500Original price was: ₨ 3,500.₨ 3,000Current price is: ₨ 3,000. -

Gucci Zig Zag Watch For Women

₨ 9,500 This product has multiple variants. The options may be chosen on the product page -

Sale!

Royal Ap Golden Watch For Ladies

₨ 5,500Original price was: ₨ 5,500.₨ 5,000Current price is: ₨ 5,000. -

Sale!

BWC Men Wrist Watch New Design

₨ 2,000Original price was: ₨ 2,000.₨ 1,500Current price is: ₨ 1,500. -

Sale!

Hublot Watch Big Bang With Date For Men

₨ 4,500Original price was: ₨ 4,500.₨ 3,500Current price is: ₨ 3,500. -

Sale!

Classic Fusion Watch For Men

₨ 3,500Original price was: ₨ 3,500.₨ 2,500Current price is: ₨ 2,500. -

Sale!

Floral Flower Watch For Girl

₨ 1,500Original price was: ₨ 1,500.₨ 850Current price is: ₨ 850. -

Sale!

Sander SMT-5180

₨ 15,000Original price was: ₨ 15,000.₨ 14,000Current price is: ₨ 14,000. -

Sale!

Potato Chipper Plastic And Stainless Steel

₨ 2,500Original price was: ₨ 2,500.₨ 1,900Current price is: ₨ 1,900. -

Sale!

2 in 1 Rechargeable Facial Hair Remover

₨ 1,800Original price was: ₨ 1,800.₨ 1,300Current price is: ₨ 1,300. -

Sale!

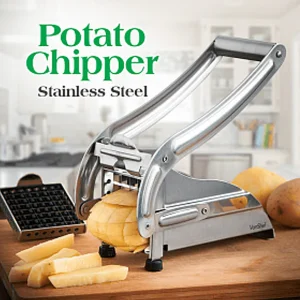

Potato Chipper Stainless Steel

₨ 3,500Original price was: ₨ 3,500.₨ 2,599Current price is: ₨ 2,599. -

Sale!

Teflon Iron Cover Protector

₨ 1,500Original price was: ₨ 1,500.₨ 799Current price is: ₨ 799. -

Sale!

5 in 1 Multi Purpose Laser Level Pro

₨ 2,500Original price was: ₨ 2,500.₨ 1,899Current price is: ₨ 1,899. -

Sale!

Combination Plier 8 Inch

₨ 1,500Original price was: ₨ 1,500.₨ 950Current price is: ₨ 950. -

Sale!

Ramdan Mubarak Foil Balloons

₨ 1,200Original price was: ₨ 1,200.₨ 1,000Current price is: ₨ 1,000. -

Sale!

16 Pack Red Tea Light Candles

₨ 2,500Original price was: ₨ 2,500.₨ 1,800Current price is: ₨ 1,800.